Industry Tests Support Need for Federal Standards and Deployment of Thermally Activated Shutoffs (TAS) Technology in the Natural Gas Industry

Industry Tests Support Need for Federal Standards and Deployment of Thermally Activated Shut-Off (TAS) Technology in the Natural Gas Industry

In 2019 The Gas Technology Institute (GTI) under the direction of their Operations Technology Deployment (OTD) Group conducted a testing program of several commercially available thermally activated shut offs (TAS) devices on the market today. The OTD Group, sponsored by several leading natural gas utilities in North America defined several key objectives for their study:

- Identify commercially available thermally activated shut-off devices available to the natural gas industry

- Evaluate the individual units’ requirements for installation

- Conduct performance testing to manufacturers designs and specifications

Specific to their evaluation GTI identified that a thermally activated shut off device may help prevent the spreading of fire at a customer premises. As a result, we believe this is a significant benefit to protecting life, property and first responders in the event of a fire.

Participating in the program were three leading manufactures of thermally activated shut-off devices including:

- TECO® SRL, the manufacturer of the FireBag®

- A prominent manufacturer of natural gas regulators who incorporates a TAS device into the unit, and

- A well-known flex hose manufacturer, which offers a thermal shut-off in their appliance connector

It is worth noting the incumbent TAS manufacturer of meter swivel connectors elected not to participate in the program.

After extensive testing and review it was determined that the TECO® FireBag®lead all technologies citing the following reasons:

- TECO FireBag offers the largest selection of sizes and fitting configurations using in the natural gas piping systems.

- Flexibility to be installed on the High Pressure (MAOP 100 PSIG) service lines as well as Low Pressure (inches water column) lines.

- Lowest shut-off trip rate temperature in compliance to MA DUP Ruling #14899

- High performance when exposed to high temperatures over prolonged periods of time as well as after the fire has been extinguished and thermal cooling has occurred.

In conclusion, the GTI Thermally Activated Gas Shut-Off testing program cited that while there is no National Standard (49 CFR Part 192, ANSI, AMSE) for thermally activated shut-off devices the natural gas distribution companies and their stakeholders would benefit by such a requirement and should explore development of such efforts for United States and Canadian standards governing the installation and operation of thermally activated shutoffs. In addition, it was identified that the industry should explore the use of high pressure (>100 PSIG) rated devices along with expanded efforts to incorporate EFV technology into these devices.

Comparative Overview

Evaluation Criteria TECO©FireBag© Regulator Design Flex Connector Meter Connection

Sizes ¾” – 2” NPT ¾” – 2” NPT 3/8”, ½”, 5/8” 5LT – 100LT

Low Pressure (inches w. c.) YES NO YES YES

Intermediate Pressure MAOP 100 PSIG 145 PSIG 5” w.c – 14” w.c. 2 PSIG

Indoor Installation YES NO YES YES

Outdoor Installation YES YES NO NO

Shut-Off Temperature 203°F – 212°F 320° F +/- 50° F 350°F – 425° F < 250°F

Manufacturing & Testing Standards DIN 3586 N/A N/A N/A

Heat Resistance 1697°F @ 60 min 1560°F 875°F N/A

How the TECO FireBag Works

The TECO FireBag Thermally Activated Shutoff (TAS) consists of a zinc-plated steel fitting containing a fusible metal alloy and spring, which when exposed to 203˚- 212˚F temperatures releases a plug producing a metal-to-metal seat, creating a gas-tight seal. Fusible alloys are a reliable technology also commonly used in emergency fire sprinkler systems. Manufactured to German DIN 3586 Standards, the TECO FireBag closes within 60 seconds of the set-off temperature and can withstand 1,697˚F for 60 minutes, allowing time for first responders to reach the dwelling and turn the gas supply off from the curb. Since the TECO FireBag is a passive device and only triggers in a fire situation, it is maintenance free, and requires no regular inspections. No fire or heat detectors are required to automatically intercept the gas flow.

Where the TECO FireBag is Used

The TECO FireBag can be installed at various locations upstream of the gas meter and is designed for use on indoor or outdoor, single meter and multi-meter installations, with pressure ratings ranging from inches water column to 100 psig MAOP.

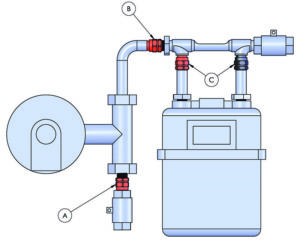

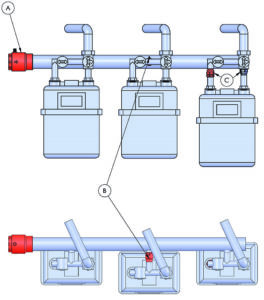

Single Residential & Multi Meter Applications

TECO FireBag Thermally Activated Shutoffs are available in multiple piping configurations and sizes to accommodate the varying piping requirements of a natural gas or propane system. A recommended TECO FireBag piping orientation and design illustration is highlighted as follows, or simply contact your local TECO FireBag distributor for additional information and specifications:

A — Upstream of the Regulator

Installed prior to the regulator, Male x Female TECO FireBag configurations are available in ¾” – 2″ NPT sizes.

Installed prior to the regulator, Male x Female TECO FireBag configurations are available in ¾” – 2″ NPT sizes.

B — Upstream of the Meter Bar

For installations after the regulator and prior to the meter bar, Female x Male TECO FireBag configurations are available in ¾” – 1½” NPT sizes.

C — In-Line with the Connection KIT utilizing existing Meter Swivels & Nuts

A TECO FireBag Meter Connection Kit can easily be installed on new or existing meter installations by utilizing a TECO FireBag fitting in-line with the inlet swivel of the meter and accompanied by a BLANK companion fitting installed with the outlet swivel, keeping the meter balanced and level. Sizes include a ½” x ¾” reducing kit, ¾”, and 1″ NPT Male x Female configurations.

TECO FireBag Thermally Activated Shutoff (TAS) Features

Fast activating trip temperatures of 203°-212°F, providing a gas-tight positive gas seal

Once triggered, TECO FireBag TAS remains active (closed) in temperatures up to 1697°F for one hour

Can undergo mechanical or thermal stress without misshaping, as thermal cooling occurs after a fire is extinguished.

Tested & Approved for gas systems operating from inches water column to 100 psig MAOP

Approved for Indoor & Outdoor piping applications

NO external power or detectors required to activate

Does not require regular inspections like active safety devices

Approved for use by Massachusetts Department of Public Utilities (DPU) – Installation and Design of Automatic Gas Shut Off Devices G.L c. 164, § 75A (2012)

Approved for use under CMR 248, Mass Fuel Gas & Plumbing Code (2011)

Over 12.5M TECO FireBag devices installed worldwide, with greater than 150,000 in the United States

Certifications

The TECO FireBag is certified for domestic and international thermal gas shutoff standards, including:

Tested and certified by Gas Technology Institute (GTI) according to DIN 3586 testing procedures (2013) (2019)

Meets and exceeds DIN 3586 thermo activated safety device for gas applications

European UNI EN 1775 Standard for indoor gas installations

European Directive 90/396/CEE certification for durability in mechanical or thermal stress

German DVGW TRGI 86/96 Standard for thermo-activated locking systems on gas heaters, water heaters & domestic gas fittings

German Standard Muster-Feuerverordnung (FeuVo v. 02/95 – edition 9/97) for thermally-activated devices

Italian UNI 7129 Ed 2001 Standard for fire protection & gas supply line components

Independently tested by GTI for OTD Member Companies

Resources

Contact Us Today!

All information is confidential and sent directly to a TECO Americas representative.

TECO® Americas, LLC

263 Cox Street Roselle, NJ 07203

inquiry@tecoamericas.com

Phone: 908-488-0909

https://tecoamericas.com