The Case for FireBag© Thermally Activated Shutoffs

Safety regarding gas pressure has taken center stage for gas companies these past two years:

- The Pipeline and Hazardous Materials Safety Administration (“PHMSA”) issued final rules amending the federal pipeline safety regulations applicable to gas transmission pipelines (effective July 2020) new rule into its operating procedures related to reconfirming maximum allowable operating pressure of gas

- Improvements to the safety and resiliency of pressure regulator station

- Installing tertiary protection at all gas regulating stations in the distribution system. This practice enhances the safety of the distribution system by reducing the risk of over-pressurization of the downstream gas system in the event of equipment failure

Given the heightened attention to safety improvements regarding the higher gas pressure prior to the regulator, many utilities are adopting automatic thermal gas shutoffs, an inexpensive technology now widely available in the United States and Canada.

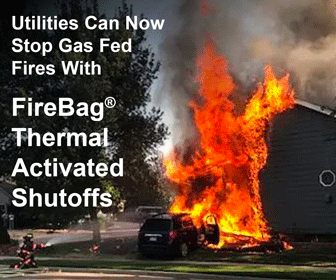

We have video documentation of the danger posed by fires fed by breached piping at the regulator and meter, as can be seen in the video of the Modesto CA fire. No utility employee or first responder wants to face the challenge of manually shutting gas flow at the meter in fire situations, as was required in the Modesto fire.

Fortunately, we now have a simple, easy, and inexpensive solution to avoid incidents such as the Modesto fire. When installed at the regulator or meter, FireBag© thermal shutoffs automatically stop the flow of gas, depriving the fire of fuel accelerant which would result in a major incident. Once the gas that flows prior to the regulator starts to feed a fire, the threat to life and property becomes much greater. At that point, first responders can no longer fight the fire, but only try to contain it from spreading to other buildings.

Safety programs are more than leak repair and safety training, although these two may pose a disproportionate share of Operations’ budgets. Given the expense to replace aging, leak-prone cast iron, wrought iron and bare steel pipe with modern plastic pipe, and exchanging residential meters with newer models that limit leakage, the additional cost of installing a FireBag thermally activated shutoff in the system offers significant improvements in overall safety at minimal expense.

Advances in Gas Safety Technology

New regulations require installation of Excess Flow Valves at the curb to provide automatic gas shutoff when gas lines are breached by backhoes. Given the significant effort to instruct homeowners on the dangers of digging near gas lines over decades of communications, breaches continued to occur, making a case for providing automatic shutoffs when the change in gas flow trips the detectors. Even though replacing curb valves is labor intensive and expensive, the investment is worth the additional level of safety.

We now have the opportunity to provide automatic gas shutoffs in fire situations at the regulator or meter at nearly no additional cost when meters are replaced.

Now that Covid restrictions are lifted, utilities are resuming their programs to exchange meters. This is the perfect time to complete the installs with FireBag thermally activated shutoffs.

Kudos to gas companies that are stepping up and provide automatic thermal shutoffs, including Wasington Gas, Con Edison, and utilities in Massachusetts – the first state in the nation that requires thermally activated shutoffs.

Resources

Contact Us Today!

All information is confidential and sent directly to a TECO Americas representative.

TECO® Americas, LLC

263 Cox Street Roselle, NJ 07203

inquiry@tecoamericas.com

Phone: 908-488-0909

https://tecoamericas.com